Industrial Valves

- Home

- What We Do

- Globe Valves

Globe Valves Manufacturers In India

Globe Valves Manufacturer in India are used generally, because of the comparatively small roughness between the sealing surface when open or closed. Also Globe Valves Manufacturer in India are durable, open height is small, manufacturing is easy and convenient maintenance, etc. It can be used not only in the low pressure but also high pressure. Globe valve closed depend on stem pressure, make the disc sealing surfaces and seat sealing surface tightly. To stop the flow of media, Globe Valves Manufacturer in India only allowed a one-way medium flowing direction, so Globe Valves Manufacturer in India are installed directional.

Globe Valves Features

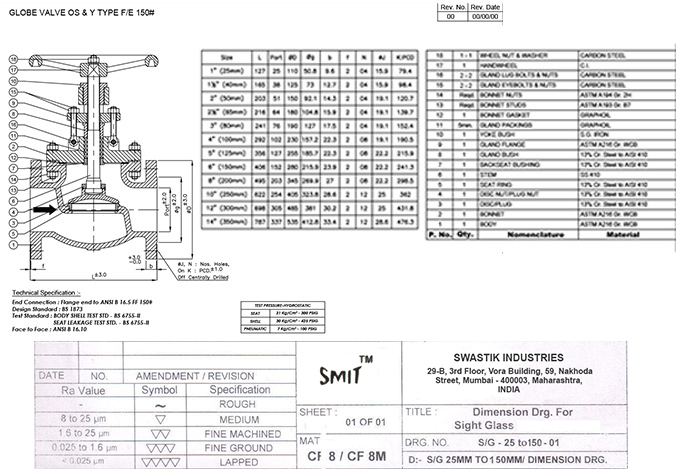

- Swastik Industries Cast Steel Globe Valves have been designed to meet the requirements BS 1873 /ASME B 16.34

- Face to Face and End to End dimensions conform to ASME B 16.10 / BS 2080 / DIN

- End flange dimensions conform to ASME B 16.5 / API 605 / BS 3293 / DIN

- Butt weld end dimensions conform to ASME B 16.25

- Anti-frictional Ball bearings are provided in higher sizes and classes.

- Outside screw and yoke construction

- All the valves are provided with backseat arrangement

- The gland is of self aligning two piece type

- Deep stuffing box

- The Seat-rings are shoulder seated type having ample cross section for strength are provided with welded in and threaded Seat-rings will be supplied on request. In case of SS valves the Seat-rings are integral to Body

- The Body to Bonnet joint is a male & female in ASME 150#, 300# & 600# valves and ring joint is used in higher classes

Options

- Angle and Y type design available

- For low temperature and cryogenic services (cold box and non-cold box applications) extended bonnet as per BS 6364 available

- Locking arrangement

- Gear, Electrical, Hydraulic or Pneumatic actuator available

- Regulating, guided and soft seated plugs available

- Bellow Seal for critical service and hazardous media

Materials

| Part Name | Material Option |

|---|---|

| Body | ASTM A 216 WCB / A 217 WC6 / A 217 WC9 / A 217 C5 / A 217 C12 / A 351 CF8 / A 351 CF8M / A 351 CF3 / A 351 CF3M/ A 352 LCB |

| Bonnet | ASTM A 216 WCB / A 217 WC6 / A 217 WC9 / A 217 C5 / A 217 C12 / A 351 CF8 / A `351 CF8M / A 351 CF3 / A 351 CF3M/ A 352 LCB |

| Disc@ | ASTM A 216 WCB / A 217 WC6 / A 217 WC9 / A 217 C5 / A 217 C12 / A 351 CF8 / A 351 CF8M / A 351 CF3 / A 351 CF3M / A 352 LCB |

| Disc Nut | ASTM A 276 410 / A 276 304 / A 276 304L / A 276 316L |

| Stem | ASTM A 276 410 / A 276 304 / A 276 304L / A 276 316L |

| Seat Rings@ | ASTM A 216 WCB / A 217 WC6 / A 217 WC9 / A 217 C5 / A 217 C12 / A 351 CF8 / A 351 CF8M / A 351 CF3 / A 351 CF3M / A 352 LCB |

| Back Seat Bushing | ASTM A 276 410 / A 276 304 / A 276 304L / A 276 316L |

| Gland | ASTM A 276 410 / A 276 304 / A 276 304L / A 276 316L |

| Gland Flange | Carbon Steel / Stainless Steel |

| Stem Nut | ASTM A 439 Gr.D2 / Al. Bronze |

| Gland Packing | Graphite Asbestos / Graphoil / PTFE |

| Bonnet Gasket | Corrugated Soft Iron / Corrugated SS / Spiral Wound SS 304 with Asbestos or Graphoil / Octagonal Ring |

| Gland Eye - Bolt & Nut | Carbon Steel / Stainless Steel |

| Cross Bolts & Nuts | Carbon Steel / Stainless Steel |

| Hand Wheel | Carbon Steel |

| Hand Wheel Nut | Carbon Steel |

| Grub Screw | Carbon Steel |

| Studs / Bolts | ASTM A 193 Gr B7 / A 193 Gr B7M / A 193 Gr B8 / A 193 Gr B8M / A 320 Gr L7 Nut ASTM A 194 Gr B7 / A 194 Gr B7M / A 194 Gr B8 / A 194 Gr B8M / A 194 Gr 4/7 |

Globe Valve 150 Class

| Size DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| **L,L1-RW,BW | 203 | 216 | 241 | 292 | 356 | 406 | 495 | 622 | 699 | 787 | 914 | 977 | 977 | 1295 |

| H (approx) | 330 | 390 | 410 | 475 | 540 | 585 | 725 | 825 | 940 | 1200 | 1270 | 1300 | 1350 | 1450 |

| ØW | 200 | 250 | 250 | 300 | 350 | 350 | 450 | 500 | 600 | 600 | 650 | 650 | 700 | 750 |

| Wt (approx) kg | 23 | 29 | 40 | 59 | 95 | 115 | 178 | 268 | 385 | 540 | 760 | 1050 | 1225 | 1650 |

Globe Valve 300 Class

| Size DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| **L,L1-RW,BW | 267 | 292 | 318 | 355 | 400 | 444 | 558 | 622 | 711 | 838 | 863 | 977 | 1016 | 1346 |

| H (approx) | 350 | 425 | 485 | 520 | 565 | 655 | 825 | 920 | 1155 | 1250 | 1295 | 1340 | 1385 | 1475 |

| ØW | 200 | 250 | 300 | 300 | 350 | 350 | 500 | 600 | 700 | 700 | 450* | 500* | 550* | 550* |

| Wt (approx) kg | 30 | 45 | 60 | 83 | 135 | 162 | 265 | 375 | 525 | 765 | 1100 | 1470 | 1680 | 2475 |

Globe Valve 300 Class

| Size DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| **L,L1-RW,BW | 267 | 292 | 318 | 355 | 400 | 444 | 558 | 622 | 711 | 838 | 863 | 977 | 1016 | 1346 |

| H (approx) | 350 | 425 | 485 | 520 | 565 | 655 | 825 | 920 | 1155 | 1250 | 1295 | 1340 | 1385 | 1475 |

| ØW | 200 | 250 | 300 | 300 | 350 | 350 | 500 | 600 | 700 | 700 | 450* | 500* | 550* | 550* |

| Wt (approx) kg | 30 | 45 | 60 | 83 | 135 | 162 | 265 | 375 | 525 | 765 | 1100 | 1470 | 1680 | 2475 |

Globe Valves Manufacturer in Mumbai

Globe Valves Manufacturer in Mumbai is a straight motion valve and is basically designed to stop, start and regulate flow. The disk of a Globe valve can be completely diminished from the flow path or it can completely close the flow path. Conventional Globe Valves Manufacturer in Mumbai may be used for isolation and choking services. Although these Globe Valves Manufacturer in India exhibit slightly higher pressure drops than straight valves but they may be used where the pressure drop through the valve is not a controlling factor at smitvalves.com

Globe Valve Manufacturer in India are extensively engaged to control flow. The range of flow control, pressure drop, and duty must be considered in the design of the Globe Valve Manufacturer in India to avert premature failure and to assure satisfactory service. Globe Valves Manufacturer in India that are required for high-differential pressure-throttling service, require especially designed valve trim. Globe Valves Manufacturer in India are used generally, for small roughness between the sealing surfaces when open or closed. Also, Globe Valves Manufacturer in Mumbai are durable, have small open height. Globe Valves Manufacturer in Mumbai is easy and convenient to manufacture as well as maintain. Globe Valves Manufacturer in India can be used not only in low, but even high pressures. The closed Globe Valve depends on stem pressure. It makes the disc sealing and seat sealing surfaces tight. To stop the flow of media, a globe valveallows only one-way medium flowing direction. However, the Globe Valves Manufacturer in Mumbai are directionally installed.

A Globe Valves Manufacturer in Mumbai is used for throttling flow control. Shut off is accompanied by the movement of the disc against the flow stream, rather than across. It is also the case of a gate valve. The flow style in a Globe Valves Manufacturer in india involves changes in direction, resulting in greater resistance to flow, and causing high pressure drop. A globe valve is an excellent valve to use for on-off service, but is absolutely suited for constant cycling and control of fluids anywhere in amount or volume between the open and closed locations. The Globe Valve Manufacturer in India must be established in proper relation to the media flow as indicated by the flow direction arrow marked on the valve body. The Globe Valves Manufacturer in India is considered uni-directional and must be installed with the pressure side or inlet under the seat.